The Innovation and Project Management Cell (IPMC) at the National Dairy Development Board (NDDB) is set up to strengthen the dairy value chain through sustainable and innovative practices. Aligned with NDDB’s commitment to innovation and continuous improvement, IPMC plays a pivotal role in designing farmer-friendly interventions and adapting to evolving challenges while upholding NDDB’s core values. Its key focus areas—renewable energy, carbon neutrality, manure management, and cooperative development—contribute to building a self-reliant and resilient dairy industry.

Objective

IPMC aims to drive sustainable growth in the dairy sector through different innovations like; renewable energy integration, waste-to-value initiatives, capacity-building for dairy farmers and cooperatives and carbon footprint reduction.

Other Linked Pages:

1. Pilots

NDDB is at the forefront of pioneering renewable energy solutions in the dairy sector, focusing on efficient manure management, biogas production, and sustainable agricultural practices. Since 2018, our initiatives have led to the development of various manure management models that promote clean energy generation while enhancing soil fertility through organic fertilizers. The Zakariyapura Model empowers rural households by converting cow dung into biogas for cooking fuel and nutrient-rich slurry for farming. The Varanasi Model, a large-scale biogas plant, integrates renewable energy into dairy processing, reducing operational costs and enhancing sustainability. Similarly, the Banas Model converts dung into Bio-CNG for vehicles, offering additional income streams for farmers and promoting carbon neutrality. These innovations, supported by government schemes and corporate partnerships, create a robust manure value chain, reducing dependency on fossil fuels and chemical fertilizers while ensuring environmental sustainability.

Beyond manure management, NDDB is revolutionizing the dairy value chain through innovative technologies. The Mobile Milk Collection System, piloted in Ladakh, enhances milk collection and testing in remote areas, ensuring transparency and fair pricing for farmers. The Farm-Level Dairy Processing Unit enables on-farm production of value-added dairy products, increasing farmers’ profitability and reducing wastage. Additionally, NDDB’s collaboration with Tata Power Renewable Microgrid Limited (TPRMG) focuses on solarizing dairy infrastructure, integrating biogas power with solar microgrids, and advancing carbon-neutral dairying. These initiatives collectively contribute to sustainable rural development, enhance energy security, and support India’s transition towards a greener, self-sufficient dairy sector.

A. Renewable Energy Initiatives: Biogas and Manure Management

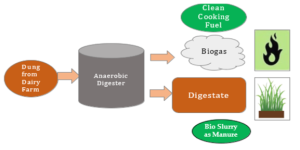

With the continuous efforts in the Manure Management domain since 2018, NDDB undertook various innovations for the efficient management of the dung. These initiatives have now resulted into development of different Manure Management Models wherein the core focus is not only in the efficient production and use of clean energy but also in propagation of sustainable agricultural practices.

Figure: Manure value chain model

A.1 Decentralised – Zakariyapura model:

To capitalise the abundant availability of dung in the rural area and making the rural households self-sustainable (Atma Nirbhar) by sufficing the requirements of energy (fuel for kitchen) and fertiliser, NDDB started the manure management initiative with few farmers in one village of Anand district in Gujarat which subsequently gained prominence as ‘Zakariyapura Model’.

Under the model, flexi biogas plants of 2 cubic meter size were installed in the backyard of the dairy farmers with the initial investment of Rs. 25,000 per plant .With the biogas plant, the beneficiary can produce clean energy equivalent to 1.5 to 2 LPG cylinders per month costing around Rs. 1,500 to 2,000. Moreover, the slurry produced from the biogas plant (having higher nutrients than Farm Yard Manure) is being utilised in the farm as a manure which is helping to reduce the dependency on the costly chemical fertilisers and improving the soil fertility.

To establish the end-to-end manure value chain, India’s first all women manure cooperative is established to process the surplus slurry at the central slurry processing centre (within the cluster of biogas plants), which converts the slurry into slurry-based value-added organic fertilisers. Hence, with the sale of the surplus slurry to manure cooperative, each beneficiary earns Rs. 1,000 to 2,000 per month depending on the quality and quantity of slurry sold.

Put together with the setup of end-to-end manure value chain, beneficiaries save or earn Rs. 3,000 to 4,000 per month which not only recovers the initial investment in the first year itself but also improves the overall wellbeing by addressing the Sustainable Development Goals such as No. 1 (No Poverty), 3 (Good Health and Wellbeing), 5 (Gender Equality), 7 (Affordable and Clean Energy), 12 (Responsible Production and Consumption) and 13 (Climate Action).

Under Manure Management initiative, more than 30,000 household level biogas plants have been installed till date with support from NDDB under various schemes of Government of India/ Corporate Social Responsibility supported by companies/ NDDB’s own funds, etc. Moreover, on the basis of success of the Zakariyapura model, several manure management initiatives at the community/ cluster level with biogas units at individual household level and centralised processing have been taken up in 11 locations (9 states) across the country. Further, NDDB’s Zakariyapura model is now included in the GOBARDhan scheme of Government of India, with NDDB as a technical partner under the scheme.

A.2 Centralised – Varanasi model:

With financial and technical support from NDDB, Varanasi Milk Union has set up a cow dung-based biogas plant which has a capacity to generate 4,000 cubic meter biogas daily. This is one of its kind of centralised model in which cow dung is procured from the farmers and the biogas generated is utilised to meet the thermal and electrical energy needs of the dairy plant for processing of milk and generation of steam etc. This model is known as the ‘Varanasi Model’.

At the 100% capacity, the plant needs 100 MT of dung per day which is aggregated from farmers and Gaushalas within a radius of about 10 to 15 km of the dairy plant to produce biogas every day. The bio slurry produced from the biogas plant is separated into solid and liquid fractions to manufacture Phosphate Rich Organic Manure (PROM). This not only promotes use of green energy but also reduces the processing cost.

While on the one hand farmers are getting price of cow dung along with milk, on the other hand along with meeting the energy requirements of the dairy plant, organic fertiliser is being produced which is improving the agricultural productivity and also improving the soil health. The plant was inaugurated by Hon’ble Prime Minister Shri Narendra Modi on 7th July 2023. With the use of the biogas in the dairy plant, it replaced the use of Light Diesel Oil (LDO) and hence, the processing cost of milk reduced by Rs. 0.40 to 0.50 per litre. Based on the learning, NDDB is in process to to replicate the ‘Varanasi Model’ in Barauni Dairy in Bihar with support of ONGC

Figure Centralised Varanasi model

A.3 Centralised – Banas model:

As a part of our Hon’ble Prime Minister’s vision to increase farmers’ income, a ground-breaking initiative in the Manure Management domain was taken by Banas Dairy by setting up a large-scale biogas unit with the raw biogas generation capacity of 2,000 cubic metres in the year 2020. The pilot project was set up in the Dama village of Banaskantha district of Gujarat which has the capacity to generate Bio-CNG from cow dung. It yields approximately 2,000 cubic meters of raw biogas daily. The generated raw biogas is compressed and purified before using as Bio-CNG for the vehicles and the bio-slurry is being utilised for the production of organic fertilisers which is now known as ‘Banas Model’ .

The primary raw material used in the biogas production process is the cow dung. The plant engages in procuring 40 MT of dung on daily basis from a network of about 250 dairy farmers situated in the nearby 12 villages. The procurement process is executed through a well-organised system involving dedicated routes in line with the milk collection system. The dairy farmers are paid an average of Rs. 1.0 per kg of dung supplied. The digested slurry is further processed to produce solid fertilisers such as PROM, Fermented Organic Manure (FOM) and liquid fertilisers. Overall, the Banas model helps provide additional income to farmers, convert cow dung to wealth, improve hygiene and environment, produce nutrient rich fertiliser and generate clean energy.

Suzuki R&D Centre India Pvt Ltd (SRDI) – a fully owned subsidiary of Suzuki Motor Corporation (SMC), Japan approached NDDB to explore possibilities of collaboration for promoting dung based Compressed Biogas (CBG) as a vehicle fuel. In this context, NDDB, SRDI and Banas Dairy have signed an agreement to take up the four such CBG projects in Banaskantha district to replicate the ‘Banas Model’.

The major objective of this collaboration is to design, develop, implement and scale up innovative business models to efficiently utilise cow dung as a source of energy for fuelling transportation needs and as a rich source of organic fertiliser while achieving carbon neutrality. SRDI wishes to promote dung based CBG stations across the country with the help of NDDB, so that CBG based affordable rural transportation can be promoted which would in turn help in achieving carbon neutrality. Continuous support is also provided for plant management and product development to make Banas BioCNG plant operations more profitable.

Figure. Centralised Banas model

NDDB has developed an expertise in different capacity biogas plants and organic fertilisers and is supporting various agencies including Banas Dairy in setting up of the different capacity biogas plants, Operations and management of plants, improving efficiencies, development of different types of organic fertilisers and strategies to propagate them etc.

NDDB has established a fully owned subsidiary named NDDB Mrida Ltd to take scale up the manure management initiatives. (A click here can take to page of NDDB Mrida Ltd)

- Innovation in Dairy Value Chain

B.1 Mobile Milk Collection System

The Mobile Milk Collection & Cooling System enhances milk collection, testing, and cooling in remote areas, ensuring fair and transparent transactions for dairy farmers. Mounted on a Maruti Suzuki Super Carry vehicle, the system includes a 300L Bulk Milk Cooler (BMC) powered by the vehicle’s engine and a Data Processor-based Milk Collection Unit (DPMCU) supported by a 100W solar panel. Piloted in Ladakh, the system improves milk quality by enabling automated testing and on-site cooling, reducing spoilage and enhancing procurement efficiency. It also ensures fair pricing through transparent milk testing and provides farmers access to organized dairy networks. The integration of solar power further enhances energy efficiency, making the system environmentally sustainable.

B.2 Farm-Level Milk & Milk Product Processing Unit

NDDB and IDMC have developed a farm-level dairy processing unit that enables farmers to produce value-added dairy products such as pasteurized milk, dahi, lassi, ghee, shrikhand, and mozzarella cheese directly at the farm A demonstration unit was established in Davalpura village, Anand district, showcasing its potential to dairy entrepreneurs across India. By decentralizing dairy processing, the unit enhances farm profitability, reduces waste, and empowers farmers to meet consumer demand for fresh, high-quality dairy products. This initiative supports long-term sustainability and self-reliance in the dairy sector.

2. Research and Development

A. Research and Development in Organic Fertiliser

NDDB completed the patent registration process for three processes: I) A System and Method for Dung Quality Testing, II) A System and Method for Bio Slurry Quality Testing and III) Process to produce granular organic fertilizer extracted from digested cattle dung. The patented process presents a potential scalable solution for ensuring quality control of dung and slurry procurement for manure management projects, quality-based fair and transparent pricing mechanism for dung and slurry payment to dairy farmers, organic fertilizer production, aligning with sustainable agriculture practices. The field testing will ensure quality control and the scalability of this technology. Further, a method to produce granular organic fertilizer from cattle dung, without the use of any binders improves the quality of the fertilizer while reducing the use of external materials.

- Efficient use of Dairy ETP Sludge

NDDB has developed a dairy Effluent Treatment Plant (ETP) sludge based organic fertiliser named as Phosphate Rich Organic Manure(PROM), aiming to provide a nutrient-rich alternative to phosphatic fertilizers. Preliminary analyses of sludge from multiple dairy plants revealed high nutrient content, prompting a scientific field experiment to evaluate its impact on pearl millet cultivation. Different formulations, including an enriched version with 8% P2O5 and with 12% P2O5, were tested against biogas slurry-based PROM and conventional fertilizers. The study focused on plant growth, nutrient uptake, and soil health, showing promising results in crop yield and soil fertility improvement.

A ETP sludge based organic fertiliser product has been developed for Banas Dairy. An exclusive ETP slurry based organic fertiliser plant is also being established in Vidya Dairy

C. Hydrogen from Livestock Manure

Advancing Hydrogen Production with Methane Pyrolysis

NDDB conceptualized and developed the idea of methane pyrolysis for hydrogen production from dung based CBG. In collaboration with Sustain Plus and Banas Dairy India’s trial plant is established in Banas Bio-CNG plant. . Using methane pyrolysis, the CBG produced at Banas Dairy is being converted into Hydrogen As the trials succeed with consistency the hydrogen produced can be blended with CBG and dispensed through existing infrastructure enhancing fuel performance. In the process of pyrolysis, carbon black will also be produced which is a valuable by-product that can be supplied to industries such as rubber, tyres, and coatings. Since the carbon black is produced from dung its potential use in agriculture too is being used.

3. Collaborations

- Project Partnership with Sustain Plus Energy Foundation

NDDB partnered with Sustain Plus Energy Foundation to replicate NDDB’s Zakariyapura Model in other parts of the country to further establish the efficacy and robustness of the model. The model was established in nine locations across seven states with partial grant support from NDDB and Sustain Plus.

Continuing the partnership, the National Dairy Development Board (NDDB) has partnered with Sustain Plus Energy Foundation to implement scalable Decentralized Renewable Energy (DRE) solutions and manure management initiatives. With a proposed outlay of ₹92.25 crore over four years, the project aims to generate additional farmer income, promote clean cooking fuel, and utilize cattle dung for sustainable agriculture. Key components include installing standalone and community biogas plants, developing manure value chains by setting up slurry processing centers, and implementing manure management models in gaushalas. The project also seeks to enhance dairy operations through mobile milk collection and testing units, farm-level milk processing, and the solarization of dairy cooperative societies etc.

- Collaboration with Tata Power Renewable Microgrid Limited (TPRMG) for solarisation of dairy value chain

NDDB and TPRMG are collaborating on various initiatives to develop and deploy indigenous, green and energy-efficient technologies across the dairy value chain and to contribute to carbon neutral initiatives such as solarization of DCSs/BMCs/Milk Chilling Centres/Dairy Plant, supplementing solar microgrid with dung-based biogas power generators for microgrids of TPRMG, energy efficient chullas (Stoves) for Biogas, application of solar dryer/solar cold storage in dairy and fruits & vegetable, the development of carbon-neutral villages, training & capacity building on Solar, etc.

The successful pilot will enable the development of commercially viable models and facilitate the propagation of this initiative across the dairy value chain in the country. This will significantly support our efforts toward achieving net-zero dairying.

- Development of Mujkuva as a Demonstration place for intervention through Cooperation

NDDB has been working with villagers of Mujkuva situated in Ankalav tehsil of Anand district in Gujarat to test pilot various interventions envisaged to be propagated in the dairy sector. These farmer centric interventions have been taken up through various farmer collectives specifically established for such activities. The village has also come up as a demonstration place for the visitors/trainee/farmers/officials visiting NDDB, AMUL, IRMA etc.

A. Four cooperative models in Mujkuva

A.1. Mujkuva Milk Producers’ Cooperative Society (MMPCS) Ltd.

The Mujkuva Milk Producers’ Cooperative Society is a progressive dairy cooperative recognized for its technologically advanced milk collection systems and strong environmental consciousness. It utilizes automated milk testing and digital payment systems to ensure efficiency and transparency for its farmer members. The society follows strict quality control measures, ensuring high standards of milk production.

Beyond dairy operations, the society actively implements sustainable practices, including water conservation, renewable energy adoption, and waste management initiatives to reduce its environmental footprint. It collaborates with local institutions and development agencies to promote climate-smart dairying and enhance the socio-economic well-being of smallholder farmers.

A.2. Mujkuva Sakhi Khad Sahakari Mandali (MSKSM) Ltd.

The Mujkuva Sakhi Khad Sahakari Mandali is India’s first women-led manure cooperative, pioneering the conversion of cattle dung into biogas and slurry which is a natural organic fertiliser. This initiative not only addresses waste management issues but also creates an additional revenue stream for women dairy farmers through the sale of slurry on the basis of quality testing. The biogas is used as an alternative to LPG in the households and is sufficient for a family of 5 to 6 members, 3 means for all every day. This results in a saving of approximately Rs 1500 per month for the dairy farmer in addition to a steady income of around Rs 2000 per month from the sale of excess slurry. The slurry is aggregated at the village level through door to door testing and collection and processed into solid and liquid fertilisers in a Slurry Processing Plant

The cooperative plays a vital role in rural women’s empowerment, as it is managed entirely by women, fostering financial independence, skill development, and leadership opportunities. It also supports sustainable agriculture by providing high-quality organic fertilizers to local farmers, reducing dependency on chemical inputs and improving soil health.

Each biogas plant of 2 m3 also reduces methane emissions to the tune of 7 tCO2e per annum thereby mitigating climate change as methane is a potent greenhouse gas.

A.3. Mujkuva Solar Pump Irrigators’ Cooperative Enterprise (MSPICE)

The Mujkuva Solar Pump Irrigators’ Cooperative Enterprise focuses on solar-powered irrigation systems, helping farmers access a reliable and sustainable source of water for agriculture. The cooperative promotes the adoption of solar energy to replace traditional diesel- or grid-powered irrigation, thereby reducing carbon emissions and lowering farmers’ operational costs.

The cooperative was inaugurated by Hon’ble Prime Minister of India in the year 2018.

A key innovation of MSPICE is its participation in solar energy trading, where farmers sell surplus electricity generated from their solar pumps back to the grid, creating an additional source of income. This model not only enhances the economic viability of solar irrigation but also contributes to India’s renewable energy transition and energy security in rural areas.

A.4. Mujkuva Organic Farmer Cooperative Society (MOFCS) Ltd.

The Mujkuva Organic Farmer Cooperative Society is committed to sustainable and organic farming practices, ensuring chemical-free, eco-friendly agricultural production. The cooperative provides training, technical support, and organic certification assistance to farmers who transition from conventional to organic farming.

The society promotes crop diversification, soil health management, and integrated pest control, reducing dependency on synthetic fertilizers and pesticides. It also facilitates market linkages, ensuring farmers receive fair prices for their organic produce through direct-to-consumer sales, farmer markets, and institutional partnerships.

Together, these cooperatives in Mujkuva serve as models of sustainability, community-driven development, and rural economic empowerment, demonstrating how innovative cooperative models can enhance livelihoods, protect the environment, and promote resilience in agriculture and dairy production.

B. Gauchar land development

In Mujkuva, a pioneering fodder land development initiative has been launched through a collaboration between the Mujkuva Dairy Cooperative Society (DCS) and the local Panchayat to address the persistent shortage of green fodder. Under this model, scientifically cultivated multi-cut Napier grass is grown on community land, ensuring a year-round supply of high-yield nutritious fodder for dairy farmers. Farmers can weigh and purchase the fodder at an affordable rate, ensuring a steady and reliable source of green feed for their cattle. This initiative not only helps improve milk productivity and cattle health but also reduces dependence on expensive, fluctuating market fodder prices. The use of scientific agronomic practices, including optimal irrigation, nutrient management, and periodic harvesting, maximizes fodder yield and enhances land productivity.

The project follows an innovative revenue-sharing model, where 75% of the revenue from fodder sales is allocated to the DCS to support dairy operations and farmer services, while 25% is directed to the Panchayat for local development initiatives. This ensures mutual benefits and incentivizes long-term participation from both stakeholders. The success of this community-driven green fodder initiative demonstrates a scalable and replicable model that can be adopted nationwide to strengthen fodder security, promote sustainable dairy farming, and create an additional income source for rural institutions. By leveraging cooperative strength and local governance, this model sets a new benchmark in fodder management, supporting both economic and environmental sustainability in the dairy sector.

- Integrated Farming System (IFS)

The IFS model has been implemented on a small dairy farm in Mujkuva. It is a holistic approach that integrates multiple farming activities, such as crop cultivation, livestock rearing, and subsidiary enterprises, in an interdependent and interrelated manner. The IFS model provides balanced food to the dairy family due to the supply of different nutrients from various components.

Cow dung is used in biogas plants, provides fuel and saves fuel wood/LPG. The IFS model provides maximum profit and regular income round the year and sustainability to the system to the small dairy farmer by combining different enterprises viz., poultry farming, goat rearing, fruit, vegetable and flower cultivation and bio-gas plant.

It also acts as a “farm school” for other small farmers, students and other stakeholders for demonstration and adoption of sustainable practices.

5. Sustainability

- Carbon credit project

NDDB along with Sustain Plus Energy Foundation (a Tata Trusts initiative) is working for the generation of carbon credits from the installation of the flexi biogas plants across 9 locations in 7 states in India. A mechanism has been developed wherein the generated carbon credits can be used to incentivise the farmers by providing an additional avenue of earning so as to ensure regular up-keep of the biogas digesters. The project has been registered under the Voluntary Carbon Standard (VCS) mechanism.

In a first of its kind project, NDDB along with SPEF partnered with EKI Energy Services limited to register a carbon credit project based on decentralised manure management, in which more than 11000 carbon credits were issued in the first year, the monetary value of which was transferred to the smallholder dairy farmers who own flexi biogas plants in their backyards.

NDDB has continued the process and all additional biogas plants being setup can now be included to avail the carbon credits.

- Carbon Footprint Assessment of Dairy Value Chain with TERI

NDDB has initiated a study on Carbon Footprint Assessment of the Dairy Value Chain with TERI (The Energy and Resources Institute) and Amul Dairy with the aim to evaluate and quantify greenhouse gas (GHG) emissions across various stages of dairy production, processing, and distribution. This comprehensive study examines emissions from livestock, fodder cultivation, manure management, milk collection, processing units, cold storage, transportation, and retail. By identifying key emission hotspots, the assessment provides insights into sustainable practices that are contributing to mitigate environmental impact and also possibility of taking up various measures , such as improved feed efficiency, biogas generation, renewable energy adoption, and efficient logistics. The study will help dairy stakeholders, including farmers, cooperatives, and processors, understand their environmental impact but also align with national and global sustainability goals by promoting low-carbon dairy production.

- Vidya Dairy Sustainability Report

NDDB supported Vidya Dairy to come out with a first-of-its-kind Sustainability Report with a comprehensive focus on Environmental, Social, and Governance (ESG) aspects, making it a pioneering effort in the Indian dairy sector. This report meticulously captures the sustainability performance of Vidya Dairy by assessing its electricity consumption, fuel usage, water management, and waste generation in dairy processing operations. It evaluates the carbon and water footprint associated with milk processing and packaging while identifying key areas for efficiency improvements. Additionally, the report documents Vidya Dairy’s various sustainability initiatives, such as the adoption of renewable energy sources, energy-efficient technologies, optimized water recycling systems, and responsible waste disposal practices. The social and governance dimensions of sustainability were also examined, highlighting Vidya Dairy’s role in skill development, ethical business practices, and compliance with regulatory frameworks. NDDB would continue to support various dairy cooperatives to come up with their own sustainability reports to showcase the promising work being carried out by them in sustainability.

- Carbon Footprint Assessment of Banas Bio CNG plant

NDDB also supported Banas BioCNG Plant to carry out Carbon Footprint Assessment by evaluating emissions reduction potential of BioCNG plants by analyzing their overall carbon footprint. This included assessing greenhouse gas emissions avoided through the use of BioCNG as a renewable energy source, replacing conventional fossil fuels, and its impact on waste management, particularly in dairy and agricultural sectors. The learnings developed are helping NDDB in supporting registration of such large scale biogas projects for availing carbon credits

- Carbon Footprint Assessment of Mujkuva Village

NDDB also conducted a Carbon Footprint Study of Mujkuva Village in terms of village’s energy consumption, transportation, agricultural activities, and livestock emissions, aiming to develop strategies for making Mujkuva a carbon-neutral village. This study considers emissions from traditional fuel use, farming practices, and dairy-related methane emissions while exploring sustainable interventions such as renewable energy integration, improved agricultural techniques, and efficient livestock management. The study has been helpful to strategies the pathway towards carbon neutrality for Mujkuva village.